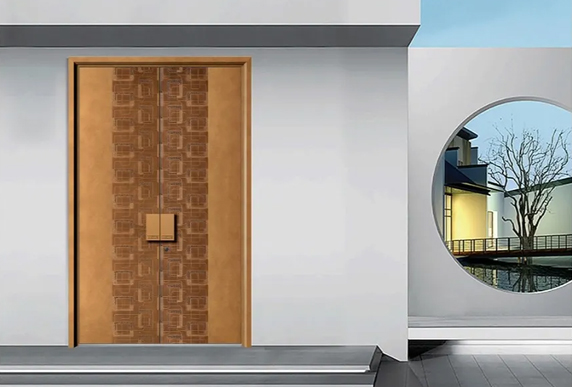

brand introduction

佛山市钰盾门业有限公司是广州市钰盾门业有限公司全资控股企业,成立于2010年,是一家集自主设计、研发、生产与销售高奢入户门产品于一体的现代化企业。现拥有广州、佛山两大生产基地,总面积达5万平米,全司员工400余人,全国专卖店约400+家,成为入户门品牌的典范。

-

15 TH

成立于2010年

2010-2024年

-

50000 m²

占地5万平方米

智能化生产车间

-

10 万

年产10万堂

高端入户门

-

400 家+

全国专卖店

-

400 人

企业员工数量